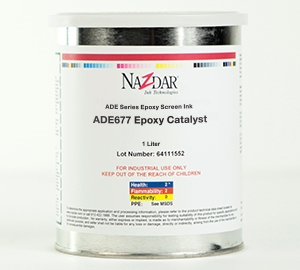

ADE677 Epoxy Catalyst

Sold at & Categories

ADE Series epoxy solvent-based screen ink has been formulated with high quality epoxy resins for excellent adhesion to metals, glass and a wide range of hard-to-print substrates. ADE Series is ideal for electronic and industrial applications and provides outstanding solvent, chemical and abrasion resistance. ADE is a two-part ink and must be initiated with a catalyst prior to use. ADE ink exhibits a high gloss finish. ADE Series is for indoor applications only.

Any additives should be thoroughly mixed before each use. Prior to production, test any additive adjustment to the ink. Inks containing additives should not be mixed with other inks.

Catalyst: The amount of catalyst should only be based on the weight of the ink and not include the weight of any other additives. Catalyzed ink requires an “induction period” or time lag of about 30 to 45 minutes. Catalyzed ink has a pot life of 6 to 8 hours.

ADE677 Catalyst: add 1 part catalyst to 5 parts ink by weight.