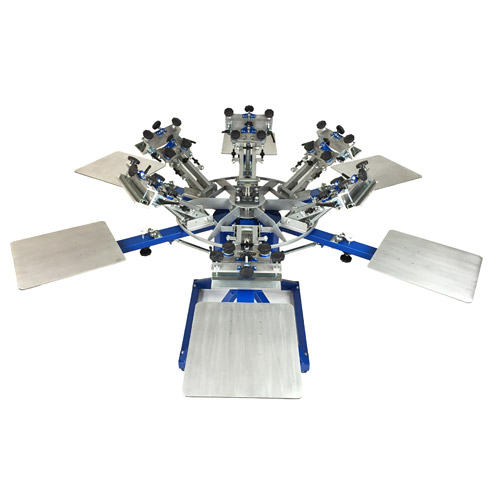

Ranar Elite Series II Textile Screen Press

Sold at & Categories

Elite Series II Textile Screen Press

The professional Elite Series II Screen Printing Presses are a proven workhorse. Designed for heavy duty use with its large screen frame capacity of 25’’ inches and comes loaded with features that would be an asset in any screen printing shop. Easy and fast to setup multi color screen printed designs with tool free adjustments for lift spring tension, micro registration, screen angle, off contact, and platen leveling. Each print head has wrap screen adjustment. A Steel key glides into 2 roller bearing which holds perfect registration from color to color.

Silk screen larger over size designs on t-shirts, textiles, signs and bags. No need to setup an automated textile printing press when printing samples the 23×31 automatic screen frames fits easily into the extra wide back or side clamps. Add the quick -release pallet option and you can use your M&R or Workhouse products automatic press aluminum platens on your manual press. Aluminum pallets are standard with the elite series presses.

Elite II Professional Screen printing presses available in:

- E-4400, 4 colors 4 stations

- E-6400, 6 colors 4 stations

- E-6600, 6 colors 6 stations

- E-8400, 8 colors 4 stations

- E-8800, 8 colors 8 stations

Rotary Multi Station Screen Printing Press

Increase production times with rotary print stations by having one person load and unload t-shirts to a conveyor dryer while the other screen prints the design. Beneficial when flash curing such as white plastisol ink as a under base then flashing and silk screening same color or another color on top of ink on dark garments to get the color to pop.

Made In the USA

The Elite Series II Screen Printing Presses are manufactured in house in the USA from the finest quality materials. All sheet steel parts are punched with CNC computer control punch press, and then formed to close tolerances. All tubular steel parts are welded in jigs to insure they are of the same quality every time. Our casted aluminum micro registration parts are precision machined to close tolerances. Our aluminum screen back clamp is extruded thru a die for uniformity and strength which holds large screen frames tight with minimal deflection. All of parts are powder coated to a glossy finish and assembled by hand to insure the screen printer has easy job set ups, increased production, and are trouble free life.

Elite Series Textile Screen Printing Press

Features:

- Adjustable Spring Tension System finger tip adjustment of the compression spring. Springs that stretch can break and flying off the press, or adding and removing springs for different size and weight screen frames. Or gas shocks that lose pressure.

- Print Head over the center design stays down till the operator raises it.

- Extra large screen capacity 25″ Inches wide

- Precision Cast Aluminum Micro Registration: allows fine precise movement of the screen frame in X, Y, and Z directions with 3 micro registration adjustor’s knobs. 2 locking knobs hold the location

- Micro Adjust easy visual micro reset to zero locaton

- Steel Index Key& Roller Bearing registration system which holds pin point registration color to color, no nylon bolts to wear out or adjusting.

- Extruded aluminum back clamp heavy duty to hold screens frame in place with minimal deflection.

- Easy tools Free Adjustments

- Adjustment knobs for off contact 1 knob with a locking knob located on each station arm to rise the screen off the platen independently.

- Screen angle adjustment knob level screen to platen with 2 locking ratchet handles.

- Uneven screen adjustment located on each screen head.

- Roller Bearing Rotation independent print head & carousel effortlessly rotate with heavy duty sealed roller bearings on a precision machined 1.3/4 inch center shaft.

- Tubular Print station arm with platen leveling strut

- Print Station Locator with adjustable detent pin

- Easy glide quick change platens loosen knobs and roll to location desired

- Pallet Ruler easy visual on the arm platen location.

- Heavy duty tubular stand wide two inch square tubing for a extremely strong stand base, which has leveling pads, wheels can be added

- Aluminum Pallet / Platen Boards are standard. Anti-warp aluminum platens, will last the life of the screen

Printing press. Made of aircraft quality aluminum, to stay flat under high heat conditions. Rubber

Surface can be added. - Ships 90% Assembled minimal assembly required

Options

- Quick Release pallet adaptor bracket interchangeable with M&R , And Workhorse Products Automatic Screen Printing Press Pallets

- Pallet Top Rubber printing surface 1/8 thick

- Side clamps Side clamps support the corners of large over size screen frames

- Squeegee Rest Brackets Adjustable location on screen

- Cap, hat printing Attachments using curved screens.

- Number printing attachment: for athletic numbering of jerseys

- Jacket Hold Down: holds nylon jackets with inner linings

- Platens / accessories coozie, zipper, oversize, youth, infant

- Vacuum table to hold delicate products without adhesive such as paper, decals, hot peel transfers