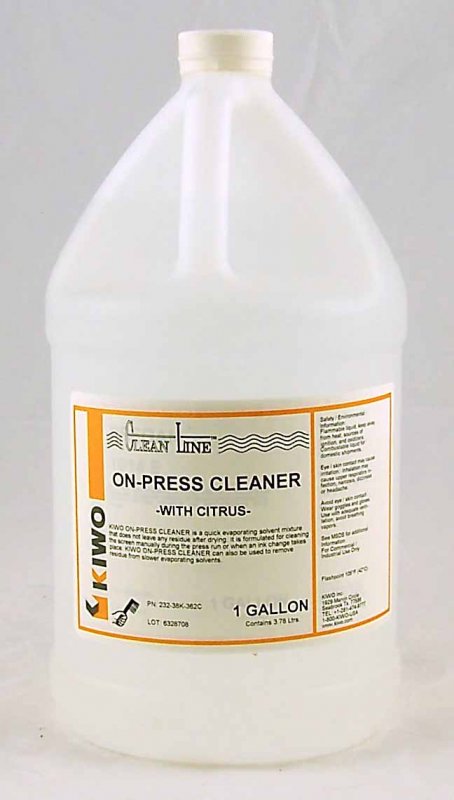

Kiwo On Press Ink Wash

Sold at & Categories

ON-PRESS CLEANER is the quickest evaporating and most effective solvent for cleaning screens on press. It does not leave an oily residue after drying; this, combined with its quick evaporation, allows for immediate tape application.

1. DESCRIPTION

ON-PRESS CLEANER is a highly effective quick evaporating solvent mixture that does not leave any residue after drying. It is formulated for cleaning the screen on press when an ink change takes place or as a screen opener. It can also be used to remove residue from slower evaporating solvents. The flashpoint and vapor pressure are balanced to allow for fast drying and modest odor.

2. APPLICATION

Before cleaning the screen, remove all ink with a scraper or spatula. Rub both sides of the screen with a rag or a brush soaked in ONPRESS CLEANER until all ink residue is completely dissolved or emulsified, and the emulsion becomes clearly visible. Finish by wiping screen with dry rag or towel to speed the drying time. Should any ink residue remain on the screen, pour ON-PRESS CLEANER onto the screen and brush the screen every few minutes until the residue is dissolved. Remove the residue with a rag. ON-PRESS CLEANER has strong cleaning power and may attack the frame adhesive if the screen is soaked in ON-PRESS CLEANER. Keep the soaking time as short as possible and if necessary, use a protective lacquer, such as ESTELAN B700-05 to protect the adhesive.